The first concept of Lean Six Sigma was created in 2001 by a book titled Leaning into Six Sigma: The Path to Integration of Lean Enterprise and Six Sigma by Barbara Wheat, Chuck Mills, Mike Carnell. Lean Six Sigma is a synergized managerial concept of Lean and Six Sigma;

In the early 2000s Lean Six Sigma principles expanded into other sectors of the economy, such as Healthcare, Finance, Supply Chain, etc.

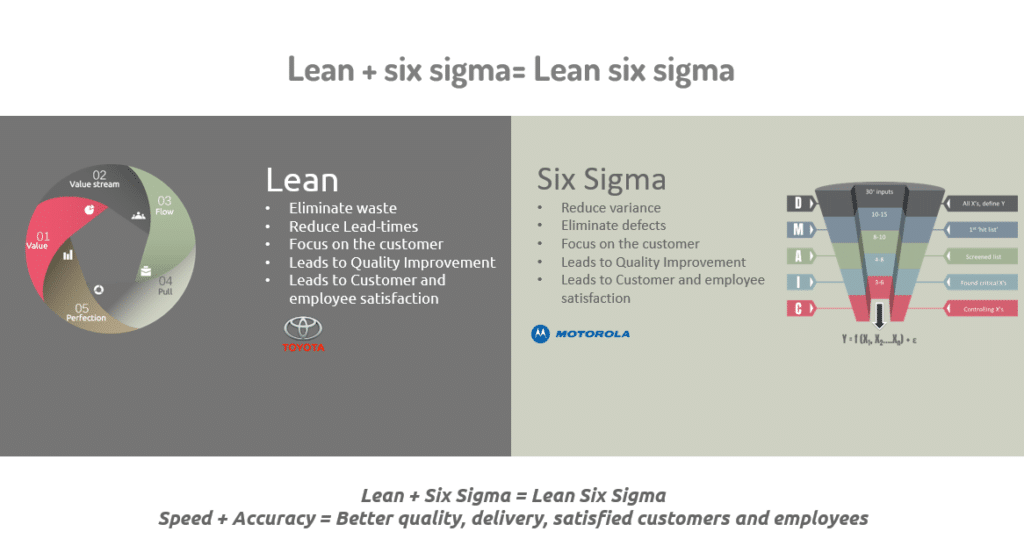

Like explained in the first blog of this series Lean traditionally focuses on the elimination of the eight kinds of waste classified as defects, over-production, waiting, non-utilized talent, transportation, inventory, motion and extra-processing.

In the second blog in this series we explained that Six Sigma seeks to improve the quality of process by identifying and removing the causes of defects (errors) and minimizing variability in processes.

Synergistically, Lean aims to achieve continuous flow by tightening the linkage between process steps while Six Sigma focuses on reducing process variation for the process steps, thereby enabling a tightening of those linkages. In short, Lean exposes sources of process variation and Six Sigma aims to reduce that variation enabling a virtuous cycle of iterative improvements towards the goal of continuous flow.

Lean six sigma organizes lean and six sigma to cut production costs, improve quality, speed up, stay competitive, and save money. From six sigma they gain the reduced variation on parts. Also, lean focuses on saving money for the company by focusing on the types of waste and how to reduce the waste. The two coming into lean six sigma to better each other creating a well-balanced and organized solution to save money and produce consistently. Lean six sigma not only reduces process defects and waste, but also provides a framework for overall organizational culture change.

Lean Six sigma certification

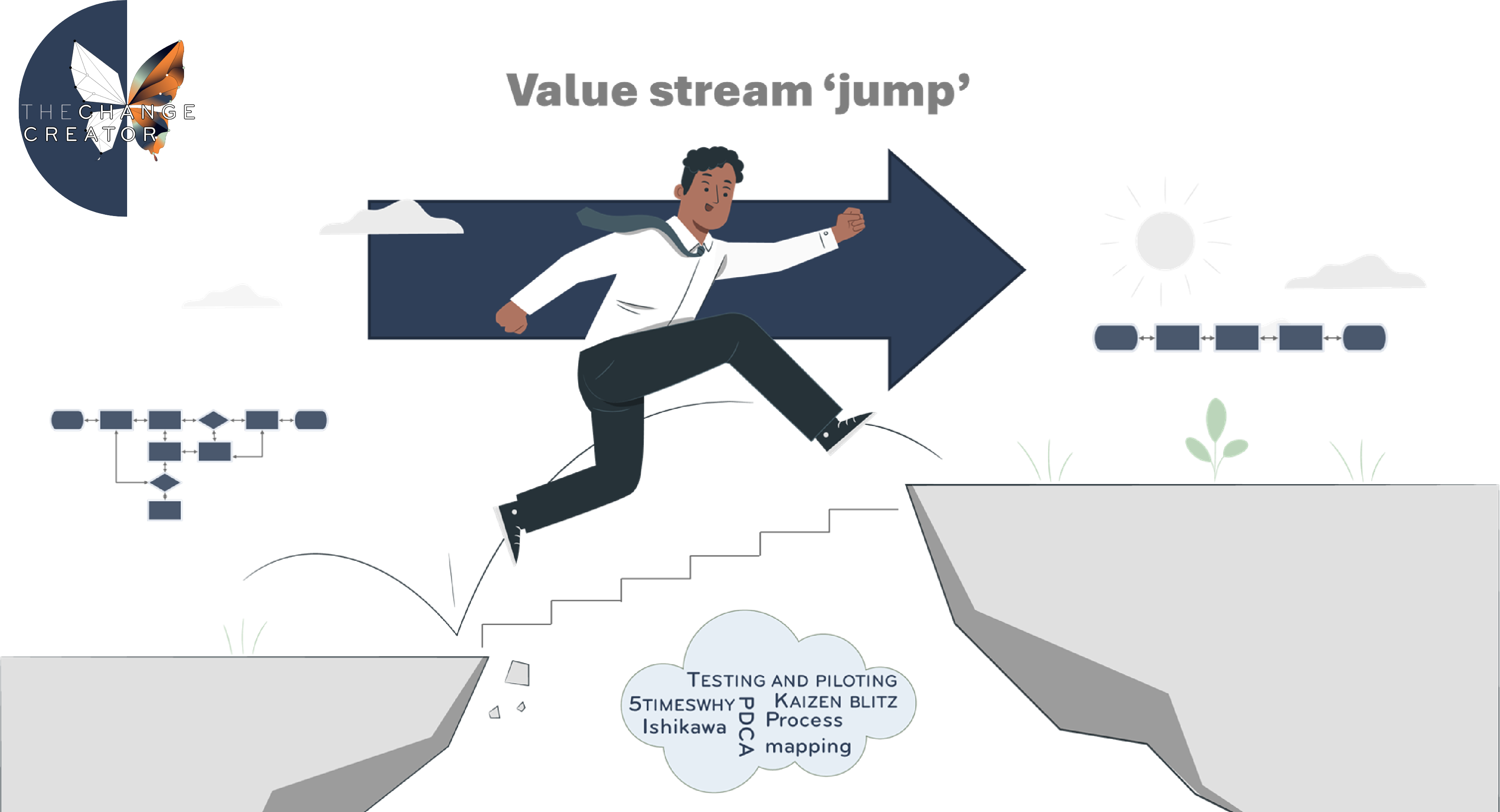

Lean Six Sigma uses the DMAIC phases similar to that of Six Sigma. Lean Six Sigma projects comprise aspects of Lean’s waste elimination and the Six Sigma focus on reducing defects, based on critical to quality characteristics. The DMAIC toolkit of Lean Six Sigma comprises all the Lean and Six Sigma tools.

The training and certification process for Lean Six Sigma is provided through the belt based training system similar to that of Six Sigma. The belt personnel are designated as white belts, yellow belts, green belts, black belts and master black belts, similar to judo.

The world leading standard for Lean Six Sigma certification is International Association For Six Sigma Certification (IASSC) Participants enroll for an exam based on the Body of Knowledge provided bij IASSC. IASSC also provides the certification process for trainers and training institutes to guarantee a high level quality on training.

Resume of this series, the truth all three methodologies work toward the same ultimate goal: eliminating waste and creating efficient processes (value for the customer). They simply take different approaches on how to accomplish this.

Lean focuses on analyzing workflow to reduce cycle time and eliminate waste. Lean strives to maximize value to the customer while using a few resources as possible.

Six Sigma strives for near perfect results that will reduce costs and achieve higher levels of customer satisfaction.

Lean Six sigma looks at ways to increase flow while focusing on achieving consistent results.

Similarity between the methodologies is that they have demonstrated that it is possible to dramatically improve the quality of your products and customer experience by improving processes.

Peggy is a Lean Six Sigma master black belt at heart, a people’s people and bridge builder.I’ve worked at large multinationals in service and production industry. I am creative,analytic with a touch of geek. I have two lovely princesses, a wonderful husband and we live in sunny Curaçao.