Now let’s take a look at six sigma. Six Sigma aims to reduce waste and it defines a defect as anything that doesn’t meet the customer’s expectations. It focuses more on eliminating any variation in the customer experience. A Six Sigma company will produce no more than 3.4 defects for every million opportunities.

Just like Lean, Six sigma is not new and has a long history before it became the methodology as we know it today. Quality control is the grandfather of Six sigma. Quality Control”, or QC, is a rather generic term. The discipline places its emphasis on controls, such as written procedures, management to ensure compliance with those procedures, solid record-keeping, training and certification, and elements of organizational culture to promote these disciplines. There were several approaches of quality control, just to mention a few:

Total quality control (TQC)(1956) Popularized by Armand V. Feigenbaum in a Harvard Business Review article and book of the same name; stresses involvement of all departments in addition to production (e.g., accounting, design, finance, human resources, marketing, purchasing, sales)

Statistical process control(SPC)(1960s) The use of control charts to monitor an individual industrial process and feedback performance to the operators responsible for that process; inspired by control systems.

Zero Defects (1960) A quality-oriented program developed in the Martin Marietta Corporation. The program’s first target was the category of large-volume, common components obtained from suppliers. The four principles are: defining quality as “conformance to requirements”; preventing defects is better than inspecting and correcting them; setting “zero defects” as the standard; and that defects cost money.

Total Quality Management(TQM)(1985) Quality movement originating in the United States Department of Defense that uses the techniques of statistical quality control to drive continuous organizational improvement. TQM looks to gain a competitive edge by increased customer satisfaction as a result of improvements in quality. Various techniques are employed, with focus on obtaining customer involvement, even as early as the design and specification phases of product development. TQM tries to manage the quality of the inputs from suppliers, as well as the efforts of front-line workers and upper management.

The Beginnings of Six Sigma

Six Sigma was introduced in the 1980’s by an engineer for Motorola named Bill Smith. Smith believed that by getting rid of variation you can improve the customer experience and increase your overall savings.

Six Sigma has helped Motorola save millions of dollars in revenue. After witnessing Motorola’s success, other companies have adopted Six Sigma and seen dramatic savings as well. General Electric, Toshiba, Bank of America, and Intel have all adopted Six Sigma principles and seen dramatic improvements.

One of the main differences between Lean vs Six Sigma is each method implements process improvement. Six Sigma does this primarily by using DMAIC. DMAIC stands for define, measure, analysis, improvement, and control. Here is a more in-depth look at each step of the process:

- Define: In this first step, you will define the problem and how it is affecting the current process.

- Measure: During this step, you will measure the current data. By examining the process that is already in place and identifying what isn’t working. You can begin finding ways to make improvements.

- Analysis: Now that you have measured all of your current data, you can begin analyzing it to get to the root of the problem.

- Improvement: This is the step where you will come up with solutions, test your solutions, and make improvements as needed.

- Control: Once you have implemented a new process you must continue to make improvements over time. These changes will only last if employees continue to refine and maintain the process.

Six sigma certification

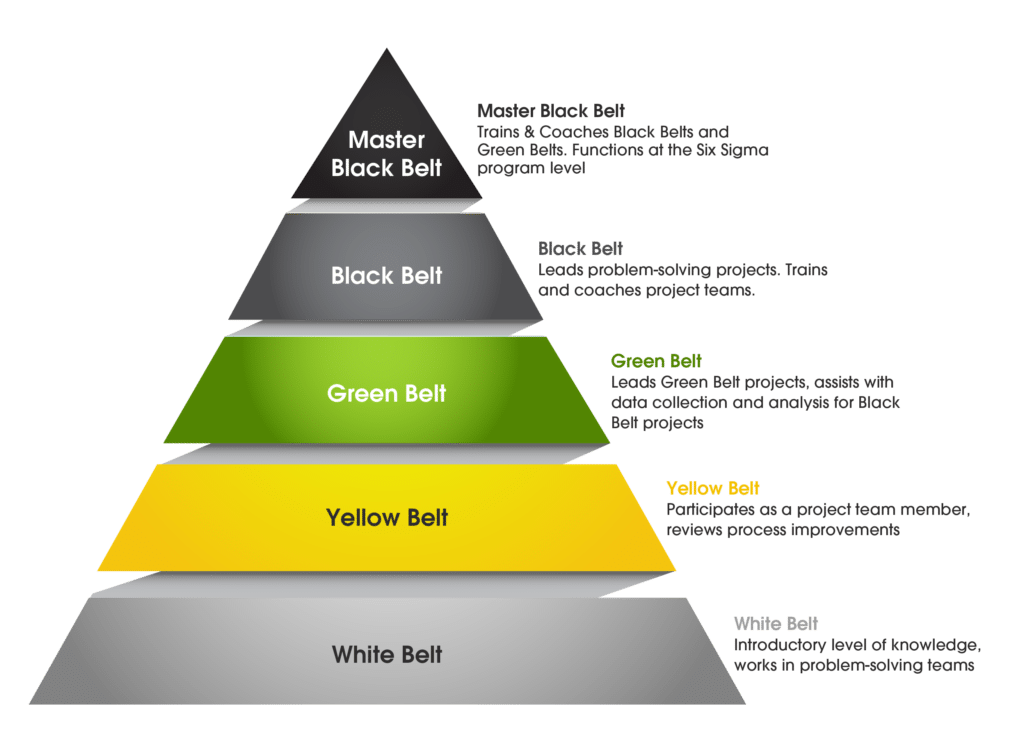

Six Sigma uses a colored belt tier system for its certification. To receive Six Sigma Certification, one must follow a hierarchical process.

Here are the Six Sigma Belt Levels you can achieve through Certification:

- Six Sigma White Belt – White belt certification demonstrates an introductory level of knowledge to the fundamental concepts of Six Sigma.

- Six Sigma Yellow Belt – Yellow Belt certification indicates that you have learned the specifics of how Six Sigma works, how it’s disciplines are applied to the workplace and where best to concentrate your time as you learn the process.

- Six Sigma Green Belt – Green Belt certification focuses on advanced analysis and resolution of problems related to quality improvement projects. Green Belts lead and manage projects, while providing support to Six Sigma Black Belts.

- Six Sigma Black Belt – Black Belt certification signifies that you are an expert in Six Sigma philosophies and principles. Black Belts are known as agents of change within an organization who lead project teams.

- Six Sigma Master Black Belt – A Master Black Belt represents the top of the Lean Six Sigma achievement structure. They have extensive experience and are leaders in their fields.

The world leading standard for Six Sigma certification is the American Society for Quality (ASQ) ASQ requires for instance Black Belt applicants to pass a written exam and to provide a signed affidavit stating that they have completed two projects or one project combined with three years’ practical experience in the body of knowledge.

Peggy is a Lean Six Sigma master black belt at heart, a people’s people and bridge builder.I’ve worked at large multinationals in service and production industry. I am creative,analytic with a touch of geek. I have two lovely princesses, a wonderful husband and we live in sunny Curaçao.